Moving a 4.5 metre-long, 1.5 tonne, Finback Whale skull. Again.

This page is an account of how we moved a 4.5 metre-long, 1.5 tonne, Finback Whale skull for the second time, but in more challenging circumstances. For an account of how the University of Cambridge Zoology Museum’s iconic 70-ft long Finback whale skeleton was safely cleaned, conserved, dismantled and packed away for the duration of the museum’s refurbishment, see this webpage:

http://www.natural-history-conservation.com/finbackblog.htm.

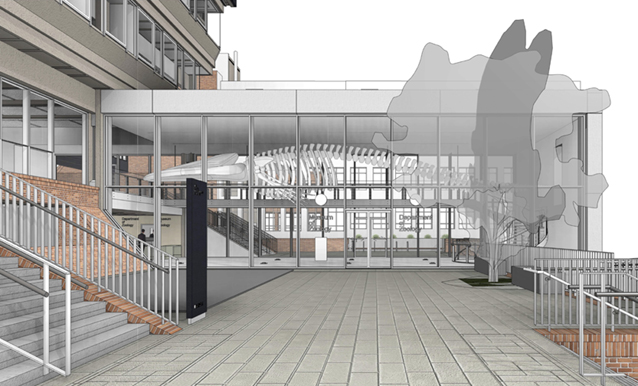

The massive 4m long, 1.5 tonne, skull was in storage for 18 months whilst the whole area was a construction site as the new ‘Cambridge Conservation Initiative’ (CCI) was built. This facility will be a unique collaboration between the University of Cambridge and the Cambridge-based cluster of leading conservation organisations as well as the Museum of Zoology. The resulting complete refurbishment of the Museum of Zoology means that exciting new displays are planned as well as the re-interpretation of all the old favourite beasts. Among the changes will be a huge new glass foyer and entrance to the museum but the massive Finback whale skeleton will still be there – in a slightly different position – to greet visitors (see image to the right).

It will simply be cleaner and will no longer be home to pigeons because it will hang inside from the ceiling of the foyer.

The massive 4m long, 1.5 tonne, skull was in storage for 18 months whilst the whole area was a construction site as the new ‘Cambridge Conservation Initiative’ (CCI) was built. This facility will be a unique collaboration between the University of Cambridge and the Cambridge-based cluster of leading conservation organisations as well as the Museum of Zoology. The resulting complete refurbishment of the Museum of Zoology means that exciting new displays are planned as well as the re-interpretation of all the old favourite beasts. Among the changes will be a huge new glass foyer and entrance to the museum but the massive Finback whale skeleton will still be there – in a slightly different position – to greet visitors (see image to the right).

It will simply be cleaner and will no longer be home to pigeons because it will hang inside from the ceiling of the foyer.

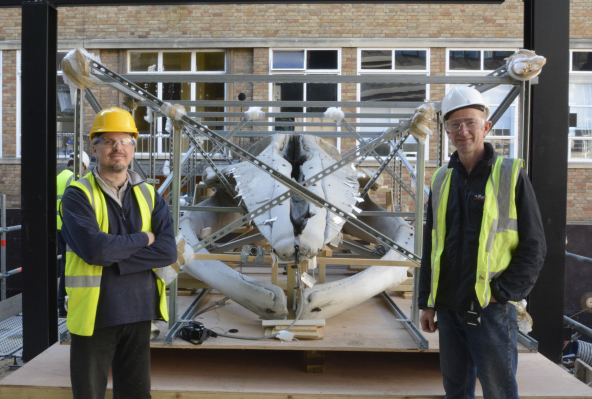

However, as the skull is about 4.5 metres long and almost 3 metres wide we could not wait until the new foyer was finished and then simply carry the skull in through the door. None of the doorways would be anywhere near big enough. So the skull needed to be moved from its temporary resting place in its shed into the foyer before the walls were covered in glass. This would be more problematic than it at first sounds: the skull and lower jaw is not only large and fragile, but very heavy (about 1.5 tonnes); it would then be sitting within a very active building site for about 6 months and would be very vulnerable to damage; and it would need to be moved occasionally as construction work would be going on all around it. To address these needs, a specialist crane and lifting team would be needed to move the heavy skull and lower jaw in the protective and supportive metal cage we had built around the skull last time we moved it; we would need to protect the skull from all possible eventualities (making protection around it that would be builder-proof, dustproof and weatherproof); and it would need to be on substantial wheels that could easily take the weight of the skull, its jaw and the protection we installed and enable it to be moved across what would still be a building site for a while yet.

Acquiring a specialist crew and crane to actually move the skull was easy enough as all sorts of heavy lifting jobs have been undertaken on site already during this project and we knew that the company ‘All Heavy’ could be trusted to undertake the work. To protect the skull from building work etc we decided that the best option would be to re-use the hefty bespoke ‘shed’ that the whale skull had been stored in for the last 18 months. This could be rebuilt around the skull on a purpose-made sturdy ‘trolley’ with large wheels that between them could take a weight of 2.5 tonnes. Yes, 2.5 tonnes: the weight of the skull and lower jaw in its protective cage plus the weight of the bespoke robust shed plus the weight of the sturdy wooden trolley itself.

A suitable date was selected that fitted-in best with the construction work i.e. as late as possible in the project so that the skull would be on the building site for the shortest time possible, but just before the walls of the foyer were installed so there was still a gap big enough to get it in. In advance of the move Phil Rye designed the ‘trolley’ that would need to take the 2.5 tonnes and sourced the appropriate wood and the specialist wheels.

Before the crane arrived to lift the skull we had three days to build the substantial trolley (5m by 3.5m, weighing about 200kg) and to dismantle the rather hefty shed and cover the skull in tarpaulin to protect it from the weather (even just the full summer sun on a clear day can damage the bones, heating them and causing them to crack). Again, all this was actually more complicated than it may sound: the space where we had to make the trolley in the car park was extremely uneven yet to make a dead flat trolley so that all the woodwork fitted properly required a flat surface to work on (we improvised with chocks), and being Cambridge we had to move the huge trolley occasionally to accommodate such things as deliveries of hydrogen, naturally. Also, last time we moved the skull it was lowered into the shed after three sides already been screwed and bolted into place, as it was designed to be connected together from the inside: but this meant that we had to dismantle the shed completely from the inside whilst the shed was almost entirely occupied by the skull! This required great strength, ingenuity and balance (the ceiling panels weighed about 40 to 50kg each) along with patience, humour and a great deal of physical flexibility to reach all the nuts, bolts and screws in all the various corners whilst not treading on or leaning on the bones that occupied most of the space and whilst negotiating the various metal struts of the protective metal cage around the skull without banging our heads or impaling ourselves.

Once the roofing felt was removed, the heavy ceiling panels taken off and the walls dismantled (so much easier said than done), we then had to protect the skull not just from the summer sun but from the storms predicted on the Friday. So we placed some of the wall panels on top of the metal cage and covered them and the whole skull with tarpaulin tied tightly to the metalwork. This meant that we had to be first on site on the Saturday morning at 0630 to remove the tarpaulin and the wall panels ready for the All Heavy crew to begin the process of lifting the skull onto the back of their flatbed lorry (on to which it would only just fit). The crane operator needed to be an experienced individual not just to carefully move the large heavy weight from the shed base to the back of the lorry but to negotiate the tight gaps and awkward angles between all the overhead cables and pipes plus the two external stairs, the nitrogen store and external generator. Just about the most awkward of spaces in which to move a fragile 4.5 by 3m skull.

Once the skull was on the back of the lorry, the driver had to negotiate the very tight angles to get around the corner and reverse into the cramped building site. During the previous week a platform had been constructed adjacent to the foyer and level with the foyer’s floor, where the skull could be lowered onto the waiting ‘trolley’ (which had itself been craned into position the day before). Again, this was a tight squeeze between the upright and horizontal beams of the foyer’s end wall and the tall fence surrounding the building site. The positioning of the skull on the trolley had to be precise, so that we stood a chance of rebuilding the shed from the inside.

We were not sure how many people it would take to move the two tonnes of skull, jaw and trolley into position but once all the wheels were lined up it was relatively easy. Easier than what followed: Phil Rye and I had to carry all the wall panels and ceiling panels onto site and up into the foyer and rebuild the shed again from the inside, clambering over and through the protective metalwork around the skull to bolt and screw all the various panels together and secure them to the trolley below, then replace all the heavy ceiling panels. We then wrapped the whole shed in a special ‘Tyvek’ fabric that would weatherproof and dustproof the contents and secured it with batons. The shed itself should be ‘builderproof’ and withstand just about all imaginable impacts and eventualities.

The skull will remain safely stored in this shed in the foyer until January or February 2016 when we will start rehanging the whole skeleton, a process that will take a couple of months. So sometime in the Spring of 2016 the whale will once again be ready to welcome visitors to the new and improved Museum of Zoology, Cambridge.

If you do not know the intriguing history of the whale and how it came to be in a museum in landlocked Cambridge, you can find out more by reading Adrian Friday’s blog here:

https://animalbytescambridge.wordpress.com/2014/02/18/finback-whale-balaenoptera-physalus/

For more details about what we can do for you, or for a quote, please

contact:

enquiries@natural-history-conservation.com

We

are members of the Institute of Conservation.